12 Features of High-Quality Butt Connectors You Should Know

Share

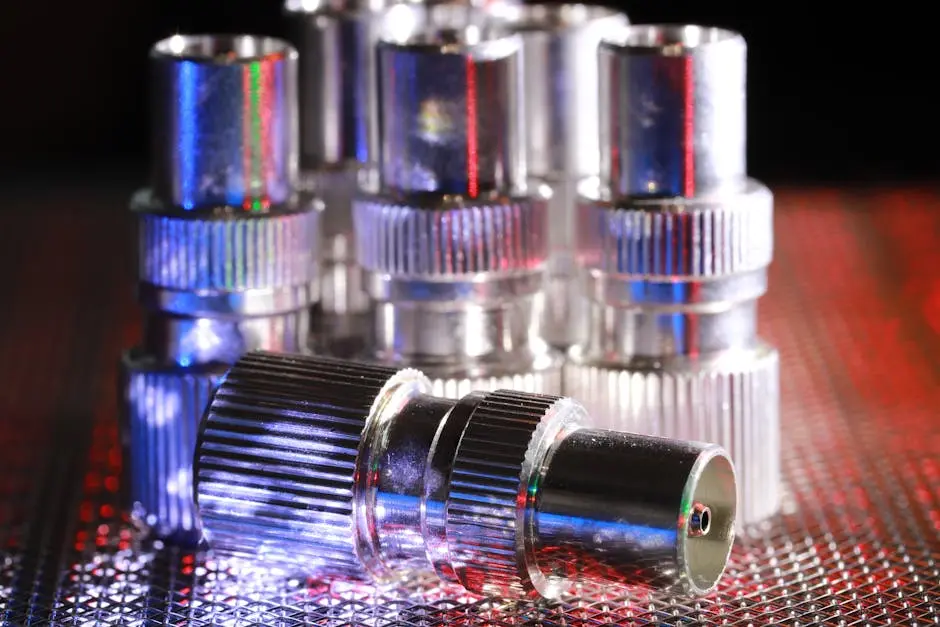

Choosing the right butt connectors is crucial for ensuring long-lasting electrical connections. High-quality connectors not only enhance performance but also provide safety and reliability. In this blog, we’ll delve into the key features that distinguish top-notch butt connectors from the rest, aiming to make your purchasing decision easier.

1. Durable Construction

High-quality butt connectors are typically made from robust materials that resist wear and tear, ensuring a secure connection over time. Materials like nylon are often used for their incredible strength, capable of withstanding physical stress without deforming. These durable connectors are perfect for use in demanding environments, such as automotive or marine applications, where vibrations and movement are frequent.

Furthermore, these connectors are usually subjected to rigorous testing procedures to meet industry standards, proving their reliability in various scenarios. Such rigorous testing ensures that they maintain integrity and provide stable connections, reducing the risk of disconnection during use. Thus, when selecting butt connectors, it’s essential to consider those with verified durable construction for investment in long-term use.

2. Excellent Conductivity

The best connectors have superior conductivity, often using materials like copper, which facilitate efficient electrical flow. Copper is an excellent conductor of electricity due to its ability to maintain a low voltage drop, which is critical in high-performance applications like power distribution. By using such conductive materials, quality butt connectors can minimize energy loss and heat build-up, promoting safety and efficiency.

In contexts where energy efficiency is crucial, these connectors become invaluable. They support consistent power transfer even under heavy loads, maintaining the operational effectiveness of your electrical systems. Therefore, choosing connectors with high conductivity can result in significant performance benefits, making them a staple component in professional and industrial settings.

3. Corrosion Resistance

To prevent degradation, top-tier connectors are designed to resist corrosion, maintaining performance despite exposure to moisture or chemicals. Corrosion is a common issue that can lead to poor electrical conductivity and the eventual failure of connections. Using connectors with anti-corrosion features is vital for systems exposed to the elements or particularly harsh conditions.

Many connectors achieve this by incorporating plated surfaces, such as tin or nickel coatings, that provide a protective barrier against atmospheric conditions. This prolongs the life of the connectors, ensuring that they remain functional over time without the need for frequent replacements, thus offering an additional economic benefit through longevity.

4. Temperature Tolerance

Quality connectors can withstand a wide range of temperatures, making them suitable for various environments and ensuring reliability. This is particularly important in industries where temperature fluctuations are common, such as HVAC systems or automotive settings. A connector’s ability to maintain structural integrity under both extreme heat and cold is indicative of its versatility and strength.

The use of specialized polymers and alloys in the construction of these connectors allows them to operate efficiently even in thermal extremes. This resilience not only enhances their durability but also ensures that they are capable of maintaining stable electrical connections in any climate, from cold storage units to hot industrial environments.

5. Secure Crimping

A strong crimp is vital for a stable connection, and quality butt connectors are designed to facilitate a secure crimping process. Secure crimping ensures that the wires are held firmly within the connector, preventing them from slipping out or becoming loose during operation. This is achieved through precision design that accommodates the appropriate wire gauge and offers adequate compression force when crimped.

The use of ratchet-style crimping tools, specifically designed for use with these connectors, further enhances the strength of the connection. This methodical approach to crimping not only guarantees a tight hold but also minimizes installation errors, thereby increasing the overall performance and reliability of the electrical assembly.

6. Flexible Fit

Versatile connectors that accommodate different wire gauges enhance usability and ensure a snug fit. This adaptability is particularly beneficial for engineers and technicians needing to work with various wire sizes during system installations or repairs. The flexibility in design means that a single type of connector can be applied in multiple applications, reducing the need for numerous different parts.

Flexible fit connectors offer ease when upgrades or adjustments are necessary, streamlining the process and reducing downtime. With properly designed connectors, the margin for error decreases, as they can adjust to the nuances of different tasks without compromising the quality of the connection. This simplifies the workflow and provides an effective solution in dynamic operational environments.

7. Simple Installation

Ease of installation is a hallmark of well-designed connectors, reducing time and effort during connection tasks. High-quality butt connectors come with features that streamline the installation process, such as easy-to-use stripping guides or color-coded indicators that match specific functions or wire types.

By minimizing complexity in both fitting and crimping, these connectors facilitate a faster setup, which is especially beneficial in large-scale projects where efficiency and turnaround times are critical. As such, these user-friendly designs promote quick and hassle-free installations, effectively reducing labor costs and improving project schedules.

8. Strong Insulation

Effective insulation prevents electrical shorts and ensures safety, a critical feature in top-grade connectors. Insulation serves as the first line of defense against electric shock hazards, protecting users and maintaining the integrity of the electrical system against interruptions.

The materials used for insulation, such as heat-resistant polymers, enhance the safety profile of the connectors. These materials not only prevent unwanted electrical conduction but also offer resistance to external factors such as moisture and chemicals, preserving the strength and longevity of the connections.

9. Vibration Resistance

Quality connectors are engineered to withstand vibrations, maintaining a stable connection in dynamic environments. This is crucial in settings such as vehicles or machinery, where constant movement can otherwise lead to loosening of electrical contacts.

Connectors that include vibration-resistant features utilize technologies like strain relief or advanced locking mechanisms that secure connections against displacement. This innovation means that even when subjected to continuous motion, the integrity of the electrical connection remains uncompromised, thus preventing potential system failures or electrical faults.

10. Clear Markings

Easy-to-read size and usage markings help in selecting and using the right connector, a minor but important feature. These markings allow for quick identification during installations or maintenance, ensuring the correct components are used without guesswork.

By removing ambiguity, these clear markings facilitate efficient and accurate assembly, particularly in high-stakes settings such as manufacturing lines or field repairs. This encourages precision and mitigates the risks associated with using incorrect or incompatible parts during electrical installations.

11. Enhanced Safety Features

Features like anti-short protection contribute to user safety and prevent electrical incidents. Enhanced safety mechanisms are crucial in ensuring that the electrical connections do not become points of failure that could potentially lead to hazards.

Incorporating these protective features can transform ordinary connectors into robust solutions tailored for critical environments. These enhancements mitigate risks and promote a safer working space by preventing inadvertent electrical discharge, thus protecting both equipment and personnel involved in the operation.

12. Cost-Effective

While high-quality connectors might be more expensive upfront, their long-term benefits and durability often lead to cost savings. Investing in superior products reduces the frequency of replacements and repairs, which can accumulate significant costs over time.

Moreover, the assurance of reduced downtime and maintenance costs associated with high-quality connectors entails a better return on investment. The initial expense is offset by the savings gained from fewer operational disruptions and the prolonged lifecycle of the electrical components, ultimately offering more value and reliability for your electrical systems.