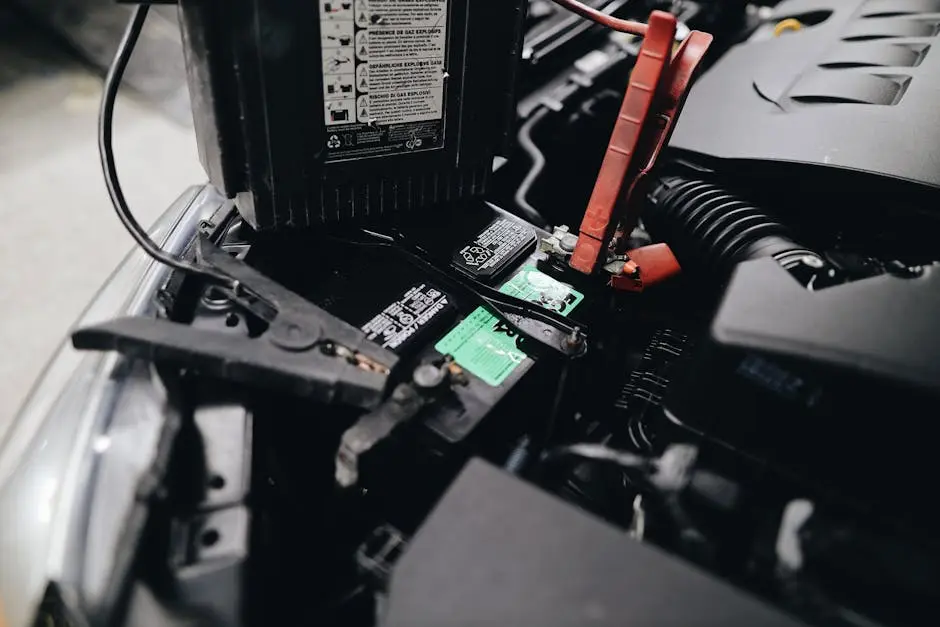

15 Common Mistakes When Installing Battery Cables and How to Avoid Them

Share

Installing battery cables might seem straightforward, but there are several common mistakes that can lead to big problems if not addressed. In this guide, we’ll explore these pitfalls and how to avoid them, ensuring your battery setup is safe and efficient.

1. Choosing the Wrong Cable Size

Selecting the correct cable size is crucial. Using a cable that is too thin can cause overheating, while one that is too thick can be unnecessarily costly and hard to work with. It’s not only about immediate efficiency but also about long-term safety. Incorrect cable sizes can lead to energy loss which affects your battery’s overall performance. Understanding the importance of cable size can help you choose wisely, ensuring optimal power flow and reducing the risk of short circuits.

2. Ignoring the Length of the Cable

Cable length affects the resistance. Longer cables increase resistance, which can lead to power loss. Always measure carefully to ensure the cable isn’t too long or too short. Remember, the right length ensures minimal resistance and helps maintain a consistent voltage to your device. Consider the physical layout too—plan your setup to minimize unnecessary bends or loops, as these add unwanted length and potential points of failure. This consideration is especially important in environments where space is at a premium and efficiency is key.

3. Failing to Secure the Connection

Loose connections can lead to arcing and power failure. Ensure all connections are tight and secure to maintain a stable power supply. Regular inspections of the terminals and connections can prevent unexpected outages. Use locking mechanisms or double-check connectors to confirm they are fully engaged. Properly securing connections not only prolongs the lifespan of your battery system but also enhances safety by preventing dangerous heat buildup from poor contacts.

4. Not Using the Correct Tools

Using improper tools can damage the cables or terminals. Invest in quality tools like wire strippers and crimpers to get the job done right. Quality tools ensure reliability in your connections and help maintain the integrity of the wire and connectors. Improperly stripped wires can lead to fraying or breakage, inefficient connectivity, and unsafe conditions. Remember, investing in the right tools can save you money and time over the long term while ensuring your setup is up to standard.

5. Overlooking Cable Insulation

Insulation is key to protecting cables from environmental damage. Damaged or inadequate insulation can lead to short circuits. Besides the visible wear and tear, it is essential to ensure that the insulation material is suitable for the environment the cables will be exposed to. Heat, cold, moisture, or chemical exposure can all weaken insulation over time, making cable failure more likely. Keep an eye on this, especially if conditions around your setup change with seasons or usage patterns.

6. Improper Grounding

Good grounding is essential for safety and performance. Ensure that cables are grounded according to manufacturers’ specifications. Proper grounding helps protect both the circuit and the user from faults that could lead to shock or fire hazards. It also aids in maintaining system stability by minimizing interference from electromagnetic fields. Always follow the guidelines provided for specific battery setups and consider seeking professional advice if unsure about the grounding process.

7. Neglecting to Test After Installation

Testing ensures everything is working correctly. Skipping this step can mean missing potential issues that could cause failures later. Conducting post-installation tests using a multimeter or other diagnostic tools can quickly reveal whether connections are secure and circuits are complete. Regular testing also helps track performance over time, allowing you to catch degradation before it becomes a significant problem. Make it a habit to test after any maintenance or significant environmental changes to keep your system reliable.

8. Using Corroded Terminals

Corrosion can impede electric flow and cause efficiency issues. Always clean terminal connections before installation. Regular cleaning of terminals with appropriate solutions helps prevent corrosion buildup, which can otherwise lead to poor conductivity. Apply anti-corrosion sprays or petroleum jelly as a preventive measure after cleaning. Corroded terminals can also lead to overheating due to increased resistance, so maintaining them is crucial for both efficiency and safety.

9. Misidentifying Positive and Negative Terminals

Connecting cables to the wrong terminals can cause serious damage. Double-check that you are connecting positive and negative cables correctly. Mismatched connections can cause immediate device failure or require costly repairs. Always follow color-coding or labeling standards to minimize errors, especially during initial installation or maintenance. Confirm connections with a testing device if you’re unsure and follow manufacturer instructions closely to ensure accurate setup.

10. Ignoring Manufacturer Instructions

Manufacturers provide specific instructions for a reason. Ignoring these can lead to improper installation and void warranties. Always read through the guidelines and make sure to adhere to them—this not only safeguards your equipment but also ensures optimal performance and safety. Manufacturer instructions often include setup tips, safe operation procedures, and troubleshooting advice that are vital for proper maintenance and operation of your battery system.

11. Not Accounting for Flexibility

Cables need some flexibility to accommodate movement and prevent stress. Rigid cables may crack under pressure and cause failures. Consider the environment and any potential physical adjustments that may occur around the battery arrangement. Flexible cables adapt better to movement and vibrations, especially in mobile or transport setups. Employ flexible connectors where needed and regularly inspect for signs of stress or wear at bends and joints.

12. Using the Wrong Type of Cable

Different types of cables are used for different applications. Make sure the cable you use is suitable for your specific battery setup. Consult with experts or resources to identify the right type of cable for your specific needs, whether you are dealing with high temperatures, heavy current loads, or exposure to the elements. Installation projects often have specific requirements that standard cables might not meet; understanding these requirements can make significant long-term differences.

13. Improper Cable Routing

Cables should be routed away from sharp edges and heat sources. Poor routing can lead to damage and reduce the lifespan of the cables. Plan your route carefully before installation, ensuring cables remain clear of interference and potential physical damage. Utilize cable ties and proper clips to secure cables along the chosen path, reducing the chance of them coming into contact with potentially harmful objects or areas. Thoughtful routing can avoid most physical damages and save costs related to premature replacements.

14. Failing to Regularly Inspect

Routine inspections can catch wear and tear before issues arise. Schedule regular checks to ensure everything is in good condition. This proactive approach helps identify potential issues such as loosening connections, corroded parts, or insulation decay. Regular maintenance aligned with inspection results can immensely extend the lifetime and reliability of your battery setup. In devices that work under tough conditions, this step is even more crucial to prolong not only cable life but also device safety and efficiency.

15. Neglecting Safety Precautions

Always follow safety protocols to protect yourself from electric shock or other injuries. Wear appropriate personal protective equipment at all times. Safety should be your top priority in any electrical project, requiring more than just protective gear – it’s about adopting an attitude of caution and mindfulness throughout the process. Keep your workspace organized and free of distractions to prevent accidents, and don’t hesitate to consult resources or professionals when tackling unfamiliar tasks.