Essential Guide to Using Butt Connectors for Durable Electrical Setups

Share

Welcome to our essential guide on butt connectors, the unsung heroes of reliable electrical setups. Whether you’re a seasoned electrician or a DIY enthusiast, understanding the proper use of butt connectors can greatly enhance the durability and safety of your projects. This guide will unravel the mysteries of these small yet mighty tools, ensuring you’re equipped with everything you need for your next electrical venture.

Understanding Butt Connectors: An Overview

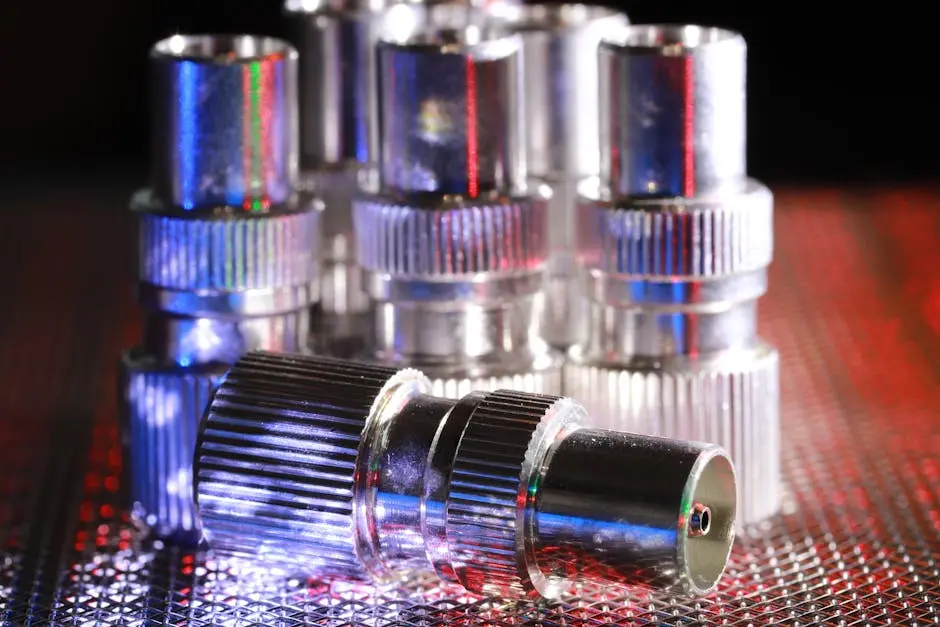

Before diving into the practical aspects, let’s explore what butt connectors are and why they are crucial for electrical connections. Butt connectors are cylindrical crimp connectors that allow two or more wires to be joined end-to-end. They provide a secure and stable connection, ensuring consistency and reliability in various electrical applications.

The simplicity of butt connectors masks their incredible utility. These connectors are vital in facilitating a seamless flow of electrical current between wire segments. Their role becomes especially evident in complex wiring projects where precision and dependability are paramount. Imagine a busy highway where each lane needs to perfectly align—this is akin to the function butt connectors serve in electrical circuits: aligning and securing pathways for electricity to travel unimpeded.

Different Types of Butt Connectors

When it comes to butt connectors, one size definitely does not fit all. In this section, we explore the different types of butt connectors available, including insulated, non-insulated, and heat-shrink variants. Each type has its specific use case, which we’ll delve into to help you choose the right connector for your needs.

Insulated butt connectors are often used in scenarios where shielding the wires from environmental factors such as moisture and corrosion is critical. Their plastic or nylon sleeves prevent short circuits and ensure safer connections. Conversely, non-insulated connectors, often favored in applications where space is constrained, provide a more direct metal-to-metal contact, enhancing conductivity in well-protected environments.

Heat-shrink butt connectors stand out due to their robust sealing abilities. After crimping, applying heat makes the connector shrink to form a tight seal, protecting the connection from fluid ingress and vibrational impact. This makes them ideal for automotive and marine applications where exposure to the elements is inevitable.

The Importance of Proper Installation

Proper installation of butt connectors is crucial to ensure a reliable connection. This section covers the step-by-step process of installing butt connectors, including wire preparation, selecting the right crimping tool, and techniques to ensure a tight fit. Following these steps will help prevent connection failures and maintain electrical integrity.

Begin by ensuring that your wires are cleanly stripped—about half an inch from their ends should suffice. Select a crimping tool appropriate for your connector type. A ratcheting crimper, for example, offers precise pressure control, preventing over-crimping that can damage both the connector and wire. As you match the connector to the wire size, a snug fit is critical to avoid slipping, which can lead to electrical failures.

Crimping is both science and art. It requires focus and an understanding of the equipment’s nuances. Start by inserting the stripped wire into the butt connector, ensuring no strands are left outside. Firmly press the crimping tool until you hear a satisfying click, indicating you’ve achieved the right pressure. Test the connection by gently tugging on the wire to ensure it’s secure.

Common Applications and Benefits

Butt connectors are widely used in various electrical applications, from automotive wiring to household projects. Here, we’ll highlight some common scenarios where butt connectors excel, and outline the benefits they bring, such as ease of use, cost-effectiveness, and enhancing connection durability.

Automotive electrical systems rely heavily on butt connectors due to their ability to maintain continuity under vibrations and extreme temperatures. Similarly, they simplify complex tasks such as house rewiring or setting up intricate lighting systems. Their compact size and reliable connections reduce the likelihood of faults, making them indispensable for both professional electricians and DIY enthusiasts alike.

In residential projects, butt connectors find ample use in appliances, light fixtures, and audio systems. Their straightforward application—simply insert, crimp, and go—eliminates much of the trial and error associated with more traditional soldering methods. The result is a quick, efficient, and highly reliable connection that stands the test of time.

Troubleshooting and Maintenance Tips

Despite their durability, butt connectors can occasionally fail if not installed correctly. In this final section, we provide troubleshooting tips for common issues, as well as maintenance advice to ensure your electrical connections remain robust over time. Implementing these tips can save you time and effort in maintaining a dependable electrical setup.

Loose connections are the bane of any electrical setup. If you notice dimming lights or intermittent appliance operation, inspect your butt connectors for signs of wear and corrosion. Reassess the crimps, as an ineffective crimp leads to greater resistance and potential overheating. Cleaning connections regularly and checking for tightness can stave off these issues before they escalate.

Heat damage is another common issue. Over-crimping or using the wrong connector type can lead to excessive heat buildup, thus deteriorating the plastic insulation and causing potential short circuits. Regularly inspect your connections for signs of melting or discoloration to prevent further damage. By taking proactive measures, you can safeguard the effectiveness of your electrical systems.

Wrapping Up Your Electrical Mastery

In conclusion, butt connectors are invaluable components in achieving durable and safe electrical connections. By understanding their types, correct installation practices, and common uses, you can ensure your electrical setups are both effective and long-lasting. Remember, the key to a successful connection lies in the details, so take the time to apply what you’ve learned and trust in the reliability of butt connectors for your projects. For more insights and electrical supplies, visit us to enhance your electrical setups.